© Website by Tooling Research Inc.

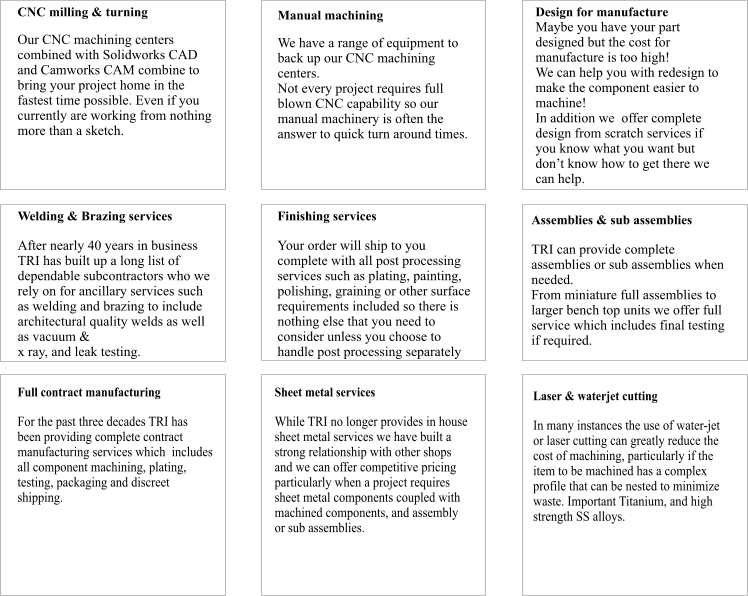

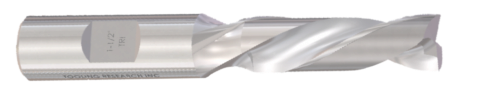

CNC milling & turning

Our CNC machining centers

combined with Solidworks

CAD and Camworks CAM

combine to bring your

project home in the fastest

time possible. Even if you

currently are working from

nothing more than a sketch.

Design for manufacture

Maybe you have your part

designed but the cost for

manufacture is too high!

We can help you with

redesign to make the

component easier to

machine!

In addition we offer

complete design from

scratch services if you know

what you want but don’t

know how to get there we

can help.

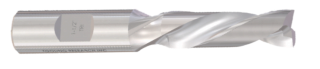

Manual machining

We have a range of

equipment to back up our

CNC machining centers.

Not every project requires

full blown CNC capability so

our manual machinery is

often the answer to quick

turn around times.

Welding & Brazing services

After nearly 40 years in business

TRI has built up a long list of

dependable subcontractors who we

rely on for ancillary services such

as welding and brazing to include

architectural quality welds as well

as vacuum &

x ray, and leak testing.

Assemblies & sub assemblies

TRI can provide complete

assemblies or sub assemblies

when needed.

From miniature full assemblies

to larger bench top units we

offer full service which

includes final testing if

required.

Finishing services

Your order will ship to you

complete with all post processing

services such as plating, painting,

polishing, graining or other surface

requirements included so there is

nothing else that you need to

consider unless you choose to

handle post processing separately

Full contract

manufacturing

For the past three decades

TRI has been providing

complete contract

manufacturing services

which includes all

component machining,

plating, testing, packaging

and discreet shipping.

Sheet metal services

While TRI no longer provides in

house sheet metal services we

have built a strong relationship

with other shops and we can offer

competitive pricing particularly

when a project requires sheet

metal components coupled with

machined components, and

assembly or sub assemblies.

Laser & waterjet cutting

In many instances the use of

water-jet or laser cutting can

greatly reduce the cost of

machining, particularly if the item

to be machined has a complex

profile that can be nested to

minimize waste. Important

Titanium, and high strength SS

alloys.

read more here

Services

Precision machining & contract manufacturing